One of our bestsellers is the orange peel grab, also known as poly grab or spiders. These are very versatile and are now the grabs of choice, especially in the recycling areas such as scrap or waste handling, but also in the loading of stone or slag. Their tasks are almost always the same: handling as much material as possible in the shortest possible time with the least amount of effort.

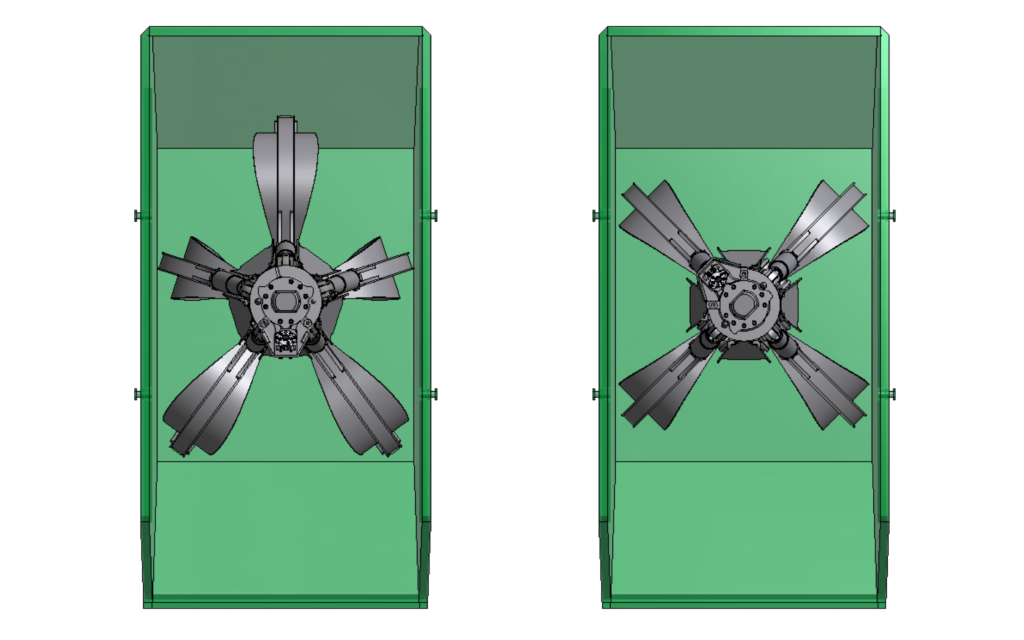

The 4-arm gripper was created for this purpose. True to the attitude “less is more”. Although the 5-arm gripper is indispensable in Europe, the advantages of four arms are obvious.

The capacity of the 4-arm version is always the same compared to the usual 5-arm grab, but the dead weight is almost 20% lower. This creates more stroke reserve for the machines without any effort. In addition, less mass has to be moved overall, which in turn saves energy (gripper weight and material picked up).

The gripper has three fewer bearing points and therefore fewer wearing parts. In addition, less oil volume is required, which helps to reduce the energy consumption of the machine.

The unbeatable opening and closing times result from the fact that four shells get into the material faster and more effectively than five. The machine only has to reclaim the volume of oil from four cylinders, not the amount from five. The weight of the saved gripper arm also has an effect here. Opening times of less than two seconds can be achieved here.

Looking now at the geometric points of the claws, the fear could flare up that small material will be lost due to the now wider gaps between the shells. Here, however, a “fixed solution” for every material is offered with different variants of the shell inner sheets.

The effectiveness of four arms to five arms can be seen in the example of car scrap loading. This gives you a secure hold when loading a body, as all arms can grip the body. A fifth arm would cause instability by pushing out of the hold.

The greater benefit of the four shells when loading containers can also be seen. An open 4-arm orange peel grab forms a square in its contour with the grab tips. Made for the dimensions of a container, right?

In the end, the operator is happy about the “accessibility” of the gripper. Due to the design, lubrication points, hose lines, bolts and bushings are easier, quicker and more service-friendly to reach and maintain. Furthermore, when investing in such devices, the missing hydraulic cylinder does not stand in the “way”, quite the opposite, of course. The high quality standard in the processing of materials, as well as the manufacturing and assembly processes, round off the “master hands” (grippers) of HGT.