Sterling Ripper literally means excellent and outstanding rock breaking equipment!

Home » Products » Korea Vibro Ripper » Sterling Ripper

Sterling Ripper literally means excellent and outstanding rock breaking equipment!

Mining

Downtown Costruction

Tunnel Construction

Underwater Operation

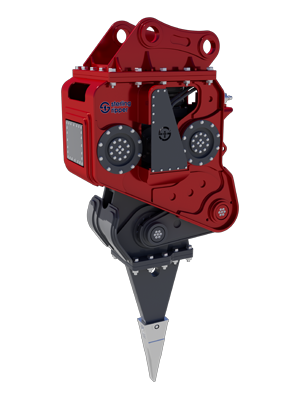

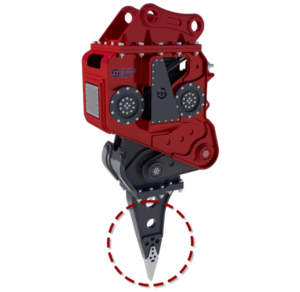

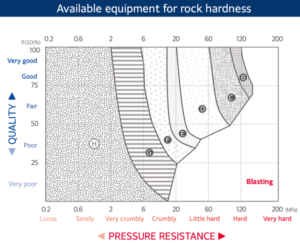

Sterling Ripper offers three options in Tooth type for soft & medium hard-rock, Chisel type for hard-rock for hard-rock, and Compactor type for compacting ground. Single Sterling Ripper body has three optional tools! you can simply change it at site any time depending on rock types and various application!

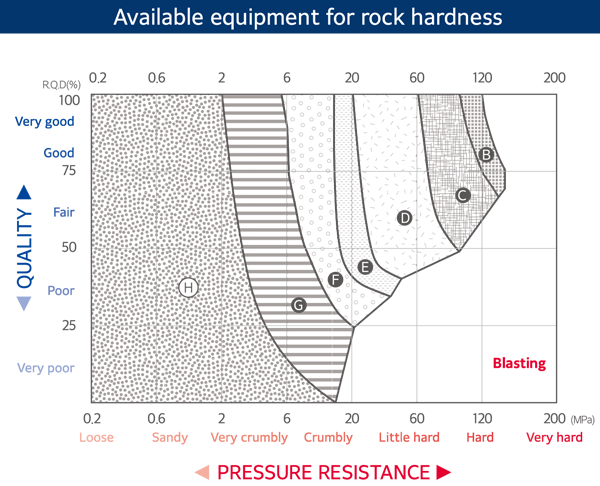

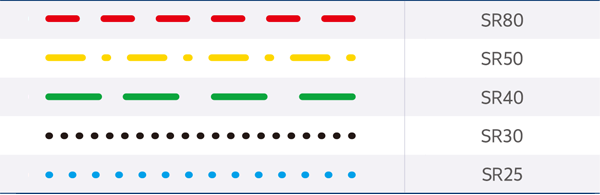

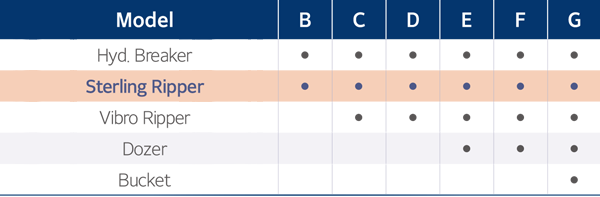

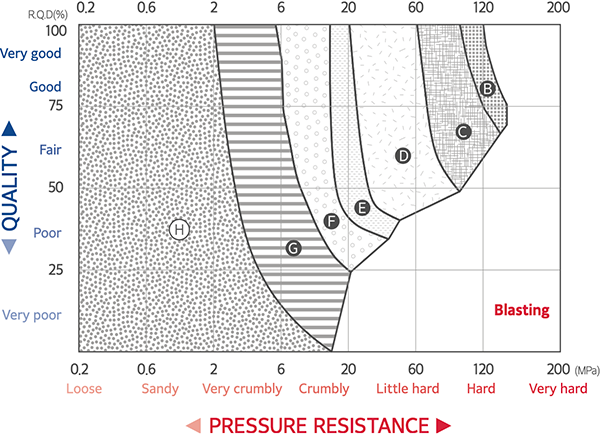

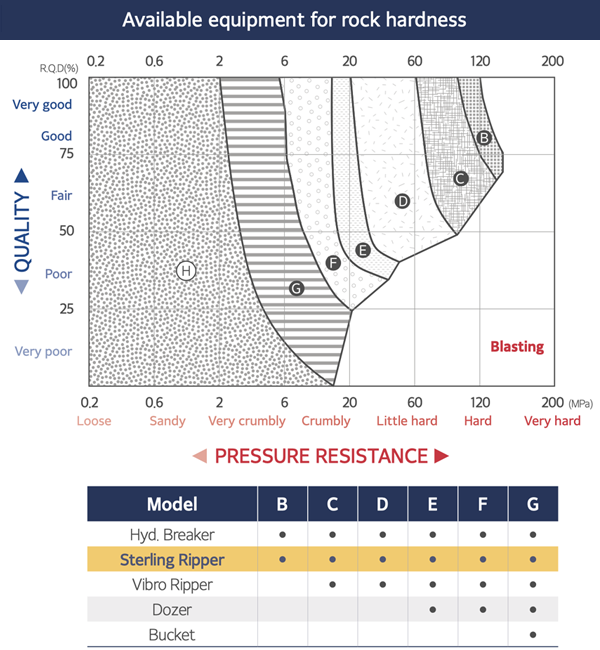

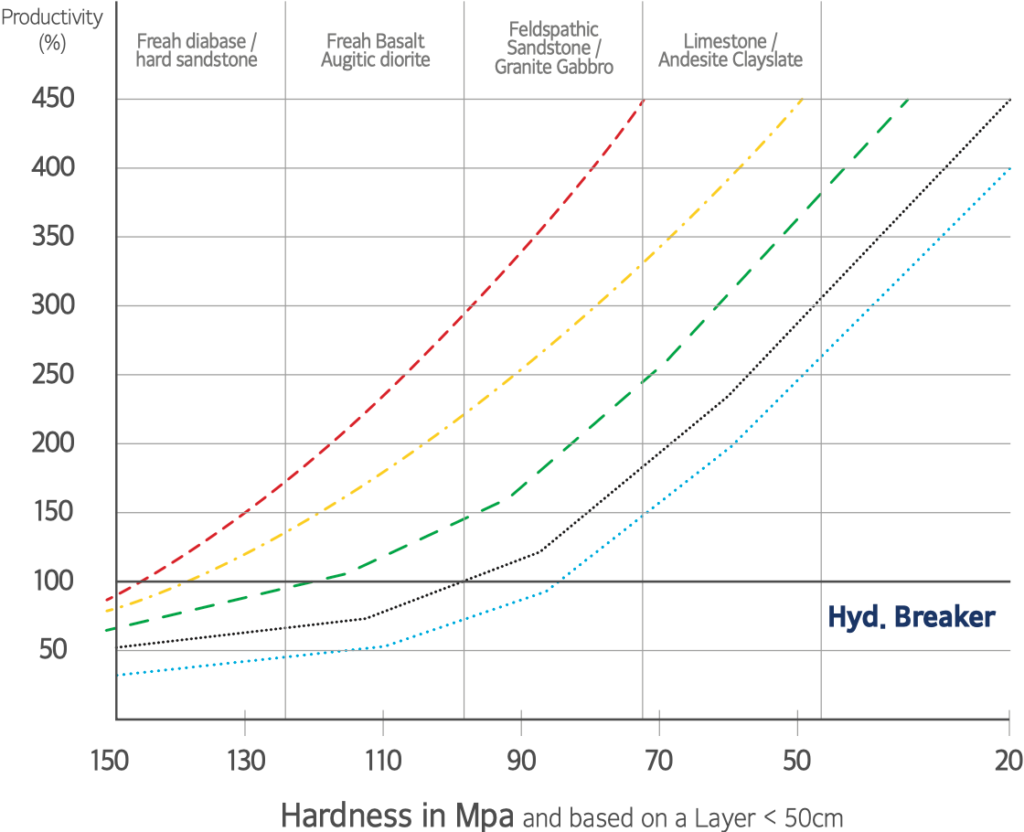

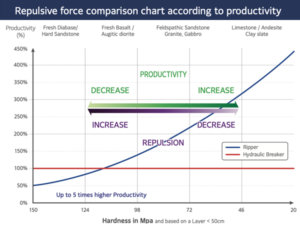

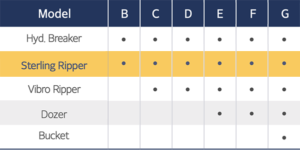

Available equipment for rock hardness

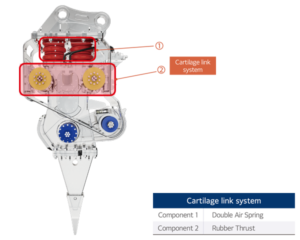

Big class Sterling Ripper can work well at hard rock without problems most vibratory rippers have, thanks to its cutting-edge technology, Unique cartilage-Link

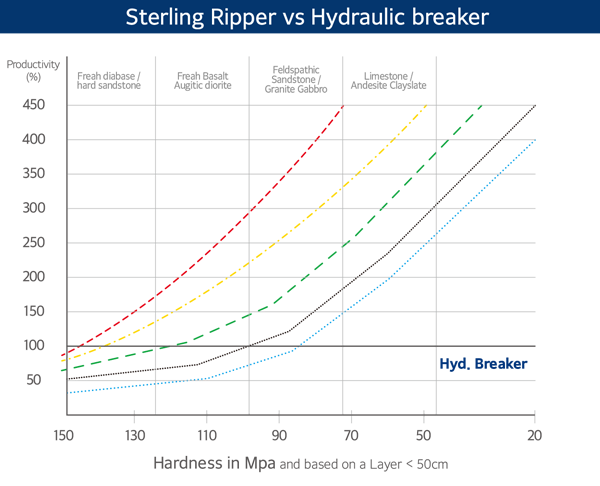

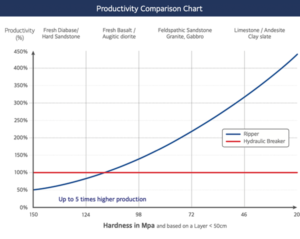

Sterling Ripper VS Hydraulic breaker

The bigger class of Sterling Ripper, the much higher productivity and hydraulic breaker up to soft medium hard-rock and perform well at hard-rock job site compared to hyd. breaker

Higher productivity than hydraulic breaker

More powerful than other vibratory rippers

Selective tool options – Three tools for one Ripper

Minimum vibration to excavator and operator at hard-rock

Minimum noise

Easy on-site maintenance & low maintenance cost

Under water operation without special devices

Vibratory Ripper’s advantages compared to Hyd. Breaker

Higher productivity than hydraulic breaker

Higher productivity than hydraulic breaker

Under water operation without special devices

Vibratory Ripper’s draw back compared to Hyd. Breaker

Solution for lower productivity than hydraulic breaker at hard-rock job sites

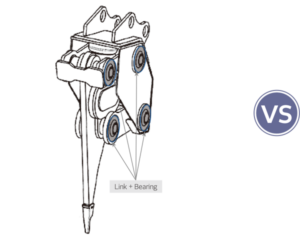

Conventional Ripper:

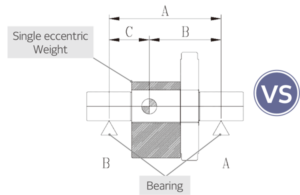

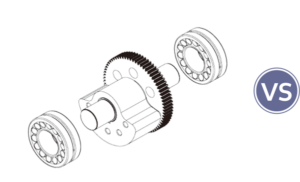

Main drawback of the link bearing structure

The links and bearings break easily working at hard-rock job sites and Ripper should be sent to maintenance shop to fix it. It takes a lot time and cost which affect total operating cost eventually

Sterling Ripper:

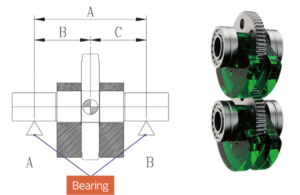

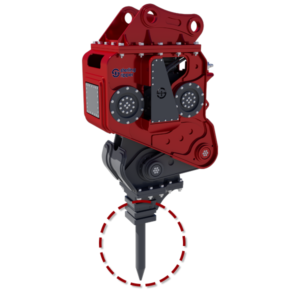

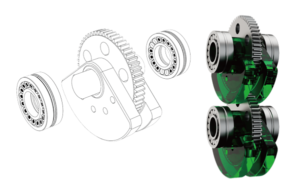

Main advantage of the cartilage link type

Sterling Ripper has adopted damper cushions with a link type instead of link bearing type. It is a very simple process of replacing cushions by simple unscrewing and screwing covers on-site, which allows can save a huge down time and maintenance cost

Conventional Ripper’s bearings vs Sterling Ripper’s Bearing

Conventional Ripper’s eccentric weight vs Sterling Ripper’s eccentric weight